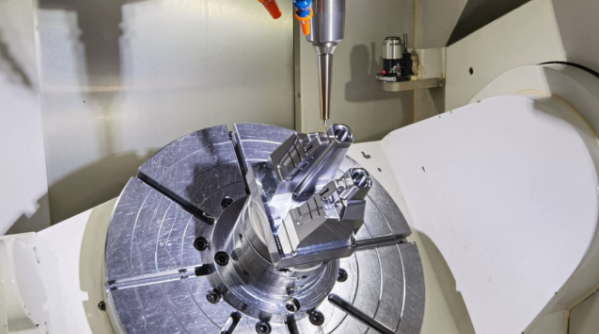

China has emerged as a powerhouse for CNC machining outsourcing in the global precision manufacturing environment, delivering a compelling combination of experience, cost-effectiveness, and technological capability. As industries throughout the world seek efficient and dependable custom component solutions, using the capabilities of Chinese CNC machining services has become a strategic decision.

The attractiveness of CNC machining outsourcing in China is based on its cutting-edge facilities, which are outfitted with cutting-edge gear and a large pool of competent engineers. Chinese manufacturers are well-known for their ability to work with a wide range of materials and complicated designs, offering everything from prototyping to large-scale manufacturing.

Another driving element behind the growing trend of outsourcing CNC machining to China is cost-effectiveness. Chinese machining firms’ inexpensive pricing, along with their commitment to quality, cnc machining outsourcing is an appealing option for organizations looking to reduce production costs without sacrificing precision.

Why Should You Use China for Your Needs in CNC Machining?

China stands out as a top choice for CNC machining needs because of its cutting-edge facilities, technological knowledge, and low cost. China, known for its extensive manufacturing infrastructure and experienced workforce, provides precision machining services at a cost advantage.

The country’s expertise in handling various materials and intricate designs makes it a top choice for organizations looking for high-quality components. Furthermore, the low cost of CNC machining in China, without sacrificing quality, presents the country as a crucial partner for companies seeking to reduce production costs while maintaining precision in their manufacturing processes.

Guide To Selecting A CNC Machining Company In China

Choosing the best CNC machining business in China is a key decision that can have a big impact on the success of your manufacturing project. China has evolved into a global hub for precision machining, providing a diverse variety of services and capabilities. This article analyses the important aspects of choosing a CNC machining firm in China, providing detailed insights into each element to help you make an informed selection.

Reputation And Experience

Begin by studying the reputation of Chinese CNC machining businesses. Investigate online reviews, testimonials, and case studies to learn about their previous performance and the experiences of other clients. A reputed business is more likely to provide high-quality services and follow industry norms. Consider the CNC machining company’s experience. Established organizations with a track record of success are frequently better able to manage a wide range of projects.

Capabilities And Services

Investigate the company’s machining capabilities. Ascertain if they have the necessary experience and equipment to handle your specific project requirements. This includes evaluating their ability to work with a variety of materials, satisfy tight tolerances, and accommodate your required production volume. Check to see whether the CNC machining company offers any additional services that will help your project.

Quality Assurance

Check to see if the CNC machining company has the necessary certifications. Certifications increase credibility and ensure that the company follows industry standards. Inquire about the quality control procedures used by the organization. Understanding their inspection techniques, testing procedures, and documentation policies will aid in ensuring that the finished products satisfy the required specifications and standards.

Technological Capabilities

Examine the type and condition of the company’s CNC machines. The company’s commitment to precision and efficiency in the manufacturing process is shown in its modern, well-maintained machinery. Check to see if they have the most up-to-date CNC equipment for your job. Check to see if the CNC machining company uses the most recent CAD/CAM software for programming and simulation. Software tool proficiency ensures reliable and efficient machining processes, lowering the chance of errors and increasing total output.

Communication and Language

Effective communication is essential for successful cooperation. provide that the CNC machining company’s team is fluent in English or your preferred language to provide clear and accurate communication throughout the process. Assess the company’s responsiveness to requests. A CNC machining partner who communicates swiftly and is more likely to resolve your problems, provide regular updates, and encourage a smoother partnership.

Cost And Pricing Structure

Understand the quoting process of the CNC machining company. A clear and complete quote should include material costs, machining fees, tooling costs, and any other expenditures. Make certain that the quote is comprehensive and clearly outlines the cost breakdown. While pricing is an important consideration, be wary of unusually cheap prices. Extremely low quotes may suggest subpar quality or hidden costs. Strive for a mix of competitive cost with quality and dependability assurance.

Lead Times And Production Capacity

Inquire about the normal lead times for manufacturing projects at the company. Understanding their lead time capabilities is critical for project planning and ensuring they can fulfill your deadline. Examine the production capabilities of the CNC machining company. It’s critical to be sure they can handle your order amount without sacrificing quality or delivery times, especially if you expect swings in your production volume.

Logistics And Shipping

Examine the company’s shipping options to see whether they match your requirements. Understanding the numerous shipping methods and the prices connected with them will aid in efficient logistics planning. Confirm that the CNC machining company has worldwide shipping experience and is knowledgeable about import/export restrictions. This knowledge is essential for avoiding potential transportation delays, customs difficulties, or complications.

Intellectual Property Protection And Geographical Location

Discuss the CNC machining company’s readiness to sign confidentiality agreements if your project contains proprietary designs. It is critical to protect your intellectual property, and a trustworthy partner should respect and uphold such agreements. Consider the CNC machining company’s geographical position in proximity to key ports. Proximity to shipping hubs can help improve logistics, thereby lowering transportation costs and lead times.

Flexibility And Adaptability

Examine the CNC machining company’s adaptability to design changes or alterations during the production process. For dynamic manufacturing projects, a partner who can react to changing project needs is essential. Consider whether the CNC machining company’s operations can be scaled to match any changes in your manufacturing volume. If your project faces growth or swings in demand, scalability is critical.

Final Words

Choosing a CNC machining company in China requires a strategic and thorough evaluation of various factors. By considering the company’s reputation, and other critical aspects, you can make an informed decision that aligns with your project requirements. A comprehensive and diligent selection process ensures a reliable and successful partnership, leading to the production of high-quality precision components.