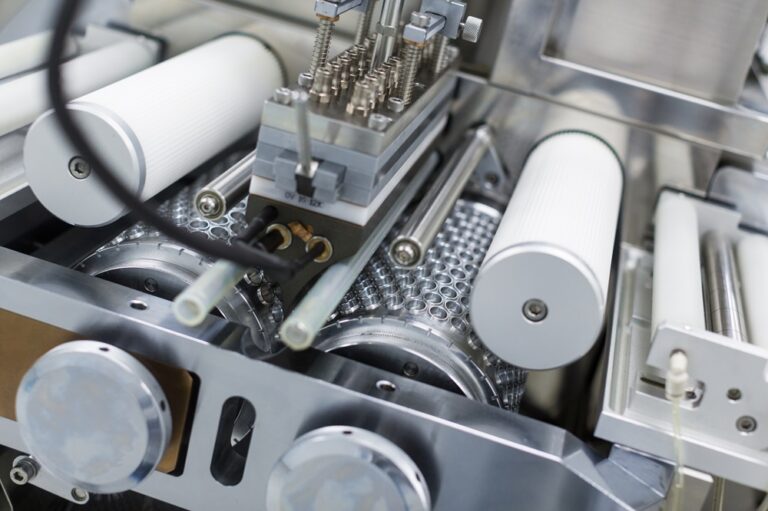

A perfect roll can make or break production efficiency. These cylindrical components are unsung heroes of manufacturing, delivering microscopic precision that affects million-dollar outputs. When rolls work correctly, production flows smoothly and output quality remains consistent. When rolls deteriorate or misalign, quality suffers immediately and expensively. The difference between acceptable and exceptional manufacturing often comes down to the precision rolls performing their functions flawlessly. Understanding precision rolls reveals how microscopic measurements translate directly into massive financial impact and production success.

Manufacturing depends on precision rolls that maintain exact specifications across thousands of operating hours. Whether processing paper, film, metal, or textiles, production lines rely on rolls that deliver consistent performance. Misalignment of even a millimeter creates visible defects that require rejection of products. Deteriorating roll surfaces create marks that downgrade product quality. That sensitivity to precision explains why precision rolls represent critical investments in manufacturing excellence.

Every perfect cut, consistent surface finish, and uniform product dimension traces back to precision rolls working exactly as designed. That precision infrastructure allows manufacturers to deliver quality consistently at scale. Understanding what makes precision rolls function and how they’re engineered reveals why they deserve attention as critical manufacturing components.

How Precision Shapes Productivity

Alignment determines whether rolls deliver consistent contact across their entire width. Misaligned rolls contact material unevenly, creating defects on one side that don’t appear on others. That inconsistency ruins products and creates quality control nightmares. Proper alignment ensures uniform pressure and contact across the entire roll width. That alignment requires precision installation and ongoing monitoring to maintain as equipment ages and components wear.

Tolerance specifications define acceptable variation in roll dimensions and performance. Modern manufacturing operates with tolerances measured in thousandths of inches. Rolls that meet those tolerances consistently deliver quality. Rolls that drift outside tolerances create problems. Maintaining tolerances requires precision manufacturing and rigorous quality control. That consistency across production batches determines whether rolls perform reliably or create problems.

Surface finish affects how material contacts the roll and how the roll treats that material. A smooth finish provides different characteristics than a textured finish. Surface contamination or deterioration changes how rolls interact with material. Maintaining surface finish through proper maintenance and occasional restoration keeps rolls performing as designed. Regular cleaning and protective storage preserve surface quality that directly impacts production quality.

The Engineering Behind Every Roll

Materials selection determines roll durability and performance characteristics. Steel rolls provide strength for heavy-duty applications. Composite materials offer advantages in specific applications. Material choice affects cost, lifespan, and performance characteristics. Engineers select materials based on specific application requirements and expected service life. That material selection represents the foundation for roll performance because no manufacturing process can overcome poor material choices.

Balancing ensures rolls rotate without vibration that would otherwise cause defects. Imbalanced rolls create oscillation during operation that translates into quality problems. Precision balancing during manufacturing creates rolls that rotate smoothly. That balance must be maintained through the roll’s lifespan, which is why balancing becomes part of maintenance routines for long-term roll performance.

Thermal control during manufacturing and operation affects roll performance and longevity. Excessive heat can degrade materials and compromise performance. Manufacturing processes must control temperature carefully to ensure quality. During operation, heat generation from friction must be managed to prevent degradation. That thermal management extends roll lifespan and maintains consistent performance across seasons and operational conditions.

Real Industries That Depend on It

Paper manufacturing depends on precision rolls that deliver consistent paper thickness and surface quality. Rolls must maintain exact specifications across massive paper widths. Any variation creates visible quality problems in the finished product. Precision in paper production translates directly into product quality that customers notice and value. Paper manufacturers invest heavily in precision roll maintenance because production quality depends entirely on roll precision.

Film production uses precision rolls to create consistent thickness in plastic films used for packaging and other applications. Film thickness variation creates problems downstream when films don’t seal properly or don’t perform as designed. Precision rolls maintain thickness consistency that packaging applications require. That consistency enables film manufacturers to deliver products that work reliably in customer applications.

Metal processing relies on precision rolls that shape and smooth metal surfaces. Textile manufacturing uses precision rolls that create consistent fabric texture and finish. In all these applications, roll precision directly determines product quality. Industries that depend on precision rolls recognize them as critical infrastructure worth maintaining carefully and replacing when necessary to maintain quality standards.

Why Calibration Is a Constant Battle

Ongoing maintenance prevents drift that would otherwise compromise precision. Regular inspections reveal wear before it becomes problematic. Cleaning removes debris that could damage surfaces. Lubrication keeps components functioning smoothly. That maintenance requires discipline and regular attention to prevent gradual degradation that eventually causes quality problems. Maintenance schedules that slip create operational risks that aren’t worth taking.

Inspection protocols verify that rolls maintain specifications throughout their service life. Measurements at regular intervals confirm alignment and surface condition. Testing under operational conditions reveals problems that static inspection might miss. That rigorous inspection reveals problems early enough for intervention before production is affected. Inspection becomes investment protection because preventive problems prevent expensive production failures.

Recalibration becomes necessary periodically as rolls age and components wear. Adjustments restore alignment and optimize performance. Restoration processes can extend roll life beyond what simple maintenance achieves. Knowing when to maintain versus when to replace becomes important judgment call that experience informs. Operators who understand roll performance recognize signals indicating that replacement or restoration becomes necessary.

Conclusion

Precision rolls translate craftsmanship into scalable industrial success by maintaining exact specifications that allow consistent quality across massive production volumes. That precision enables manufacturers to deliver reliable products that customers depend on. Manufacturing excellence depends fundamentally on components like precision rolls performing flawlessly throughout their service life.

The microscopic precision that precision rolls maintain creates massive financial impact through consistent quality, reduced defects, and production efficiency. That impact often remains invisible because when rolls work perfectly, products flow through production without interruption. That invisibility doesn’t diminish the criticality of precision roll performance.

Invest in precision rolls from manufacturers who understand specific application requirements. Maintain rolls carefully through scheduled maintenance and inspection. Replace rolls when they drift beyond acceptable specifications. That commitment to precision roll excellence directly supports manufacturing quality and production success across industries.